Commutator for Z900 Large DC Motor: An In-Depth Exploration

Introduction

The commutator is essential for DC motors, acting as a rotary switch. It reverses the current direction between the rotor and the external circuit. Specifically, in the Z900 Large DC Motor, it ensures reliable performance.

Understanding the Commutator

What is a Commutator?

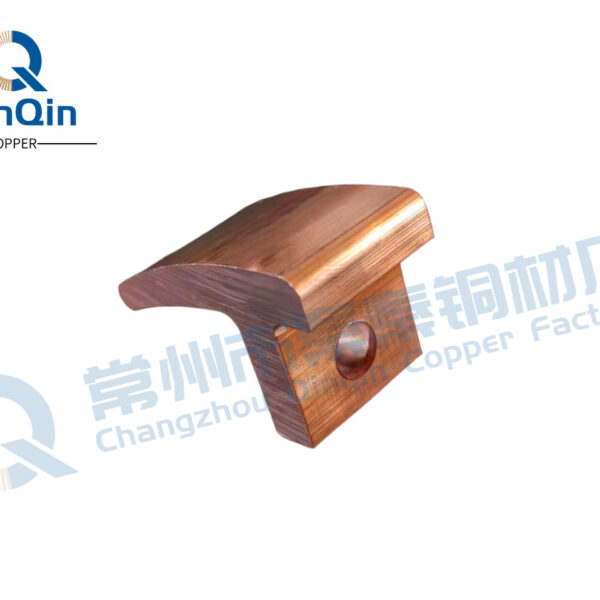

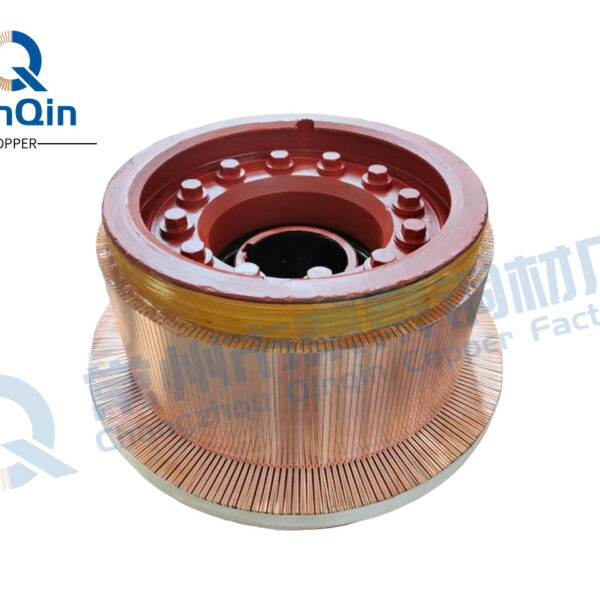

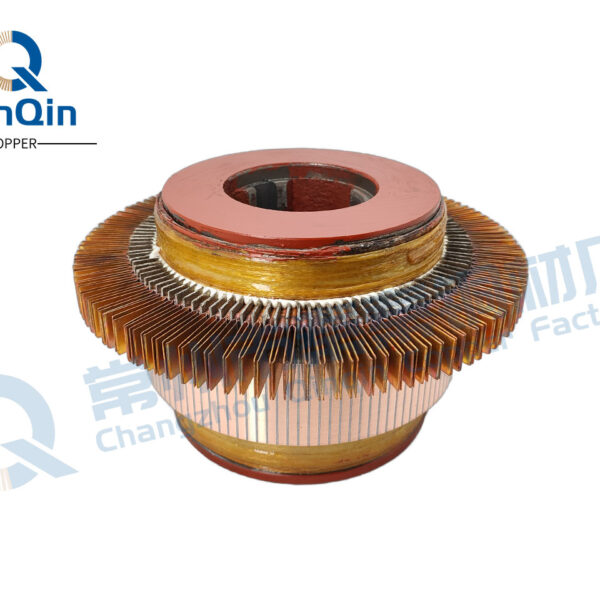

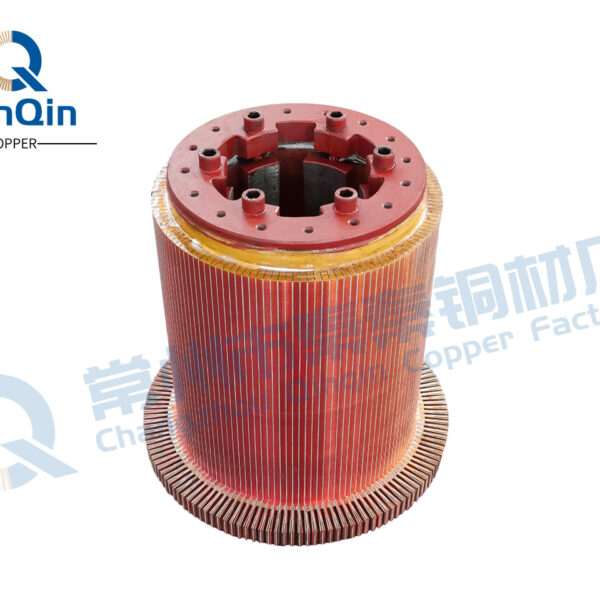

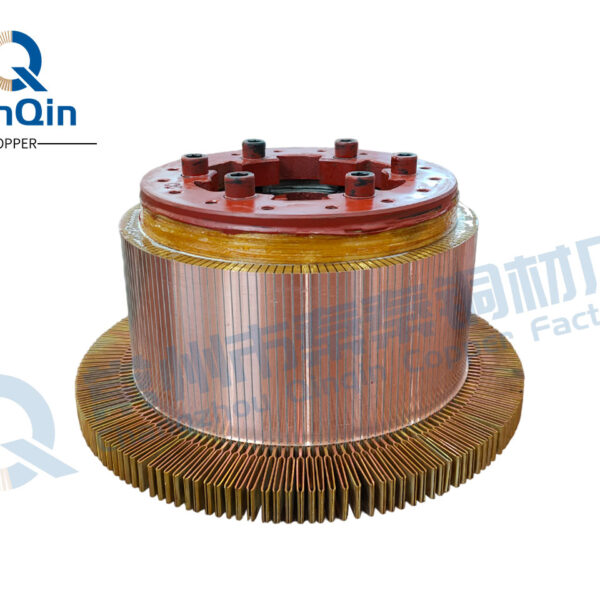

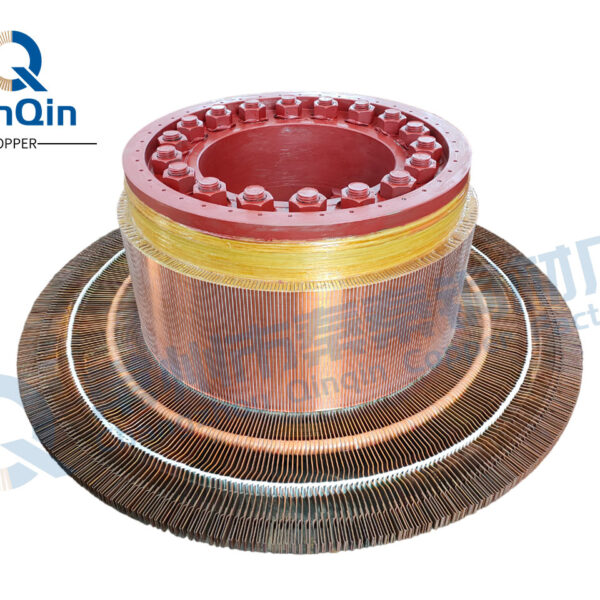

It is a cylindrical assembly of copper segments on the rotor shaft. It reverses current in the motor windings, allowing continuous rotation. Furthermore, carbon brushes maintain electrical contact with the segments, thereby ensuring efficient operation.

Functionality in the Z900 Motor

In the Z900 Large DC Motor, the commutator handles high currents smoothly. Moreover, its design minimizes sparking, thus enhancing efficiency and longevity. Consequently, the motor operates reliably under demanding conditions.

Design and Construction of the Z900 Commutator

Materials and Manufacturing

First, high-quality copper provides excellent conductivity. Additionally, segments are insulated with mica, thereby preventing electrical shorts. As a result, precise machining ensures reliability and durability.

Key Design Features of the DC Motor Commutator

- Segment Configuration: Matches the motor’s winding for optimal performance.

- Insulation: Uses high-grade materials for safety.

- Brush Contact: Minimizes friction and wear, which in turn extends lifespan.

Importance in Motor Performance

Efficiency and Reliability of the Z900 Motor

The commutator maintains optimal torque and speed by ensuring consistent current flow. Furthermore, its robust design reduces maintenance needs. Therefore, users experience fewer disruptions and increased productivity.

Impact on Longevity

A well-designed commutator extends motor life by reducing wear. Therefore, regular maintenance further enhances longevity. Thus, the motor remains efficient over time, providing long-term value.

Maintenance and Troubleshooting for the Commutator

Common Issues

However, sparking can indicate worn brushes or damage. Regular inspection is essential. In addition, wear and tear can be mitigated through regular maintenance. Thus, potential problems are addressed early, preventing major issues.

Maintenance Tips for Optimal Commutator Performance

To ensure optimal contact, regularly replace brushes. Additionally, keep the commutator clean to prevent debris buildup. Moreover, promptly address any signs of wear, thereby ensuring smooth operation and extending the motor’s life.

Conclusion

In conclusion, the commutator is vital for the Z900 motor’s performance. By understanding its design and maintenance, users can ensure efficiency and reliability. As a result, the motor continues to perform at its best, offering consistent results.